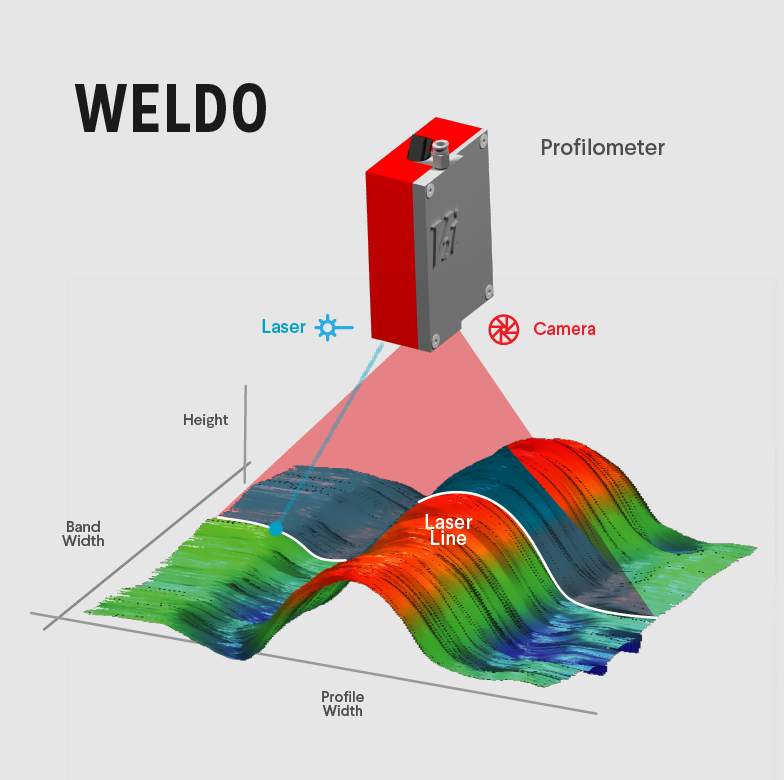

V2i offers tailor-made solutions (hardware & software) for inspection, defect detection systems and specific solutions for the monitoring of machinery.

Inline Quality Inspection for Production Lines

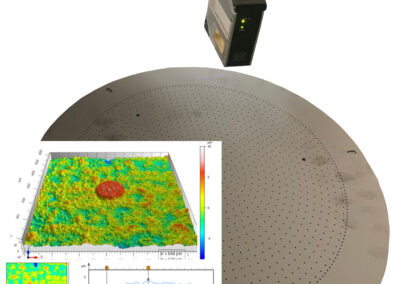

In the fast-paced world of manufacturing, quality inspection is a crucial step at the end of production lines. Traditionally, this process has been conducted visually by human operators, a method that, while effective, is time-consuming and prone to human error. As manufacturing processes become more complex and production rates increase, the need for more efficient and accurate quality inspection methods becomes paramount.

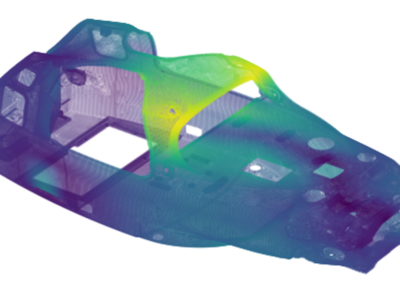

Enter the world of advanced technology solutions: 3D laser scanners, machine vision cameras, and artificial intelligence (AI). These tools are transforming the way businesses approach quality inspection by automating the process, increasing accuracy, and significantly reducing inspection times.

Our Cutting-Edge Solution: Precision and Integration at Your Service

At V2i, we specialize in integrating state-of-the-art quality inspection technologies into your existing production lines. Here’s what makes our solution stand out:

Expert Integration with Leading Technology Providers:

We maintain long-term collaborations with top-tier providers of 3D scanners and machine vision cameras. This ensures that you receive the most advanced and reliable technology in the industry, seamlessly integrated into your manufacturing processes.

Certified and Experienced Development Team:

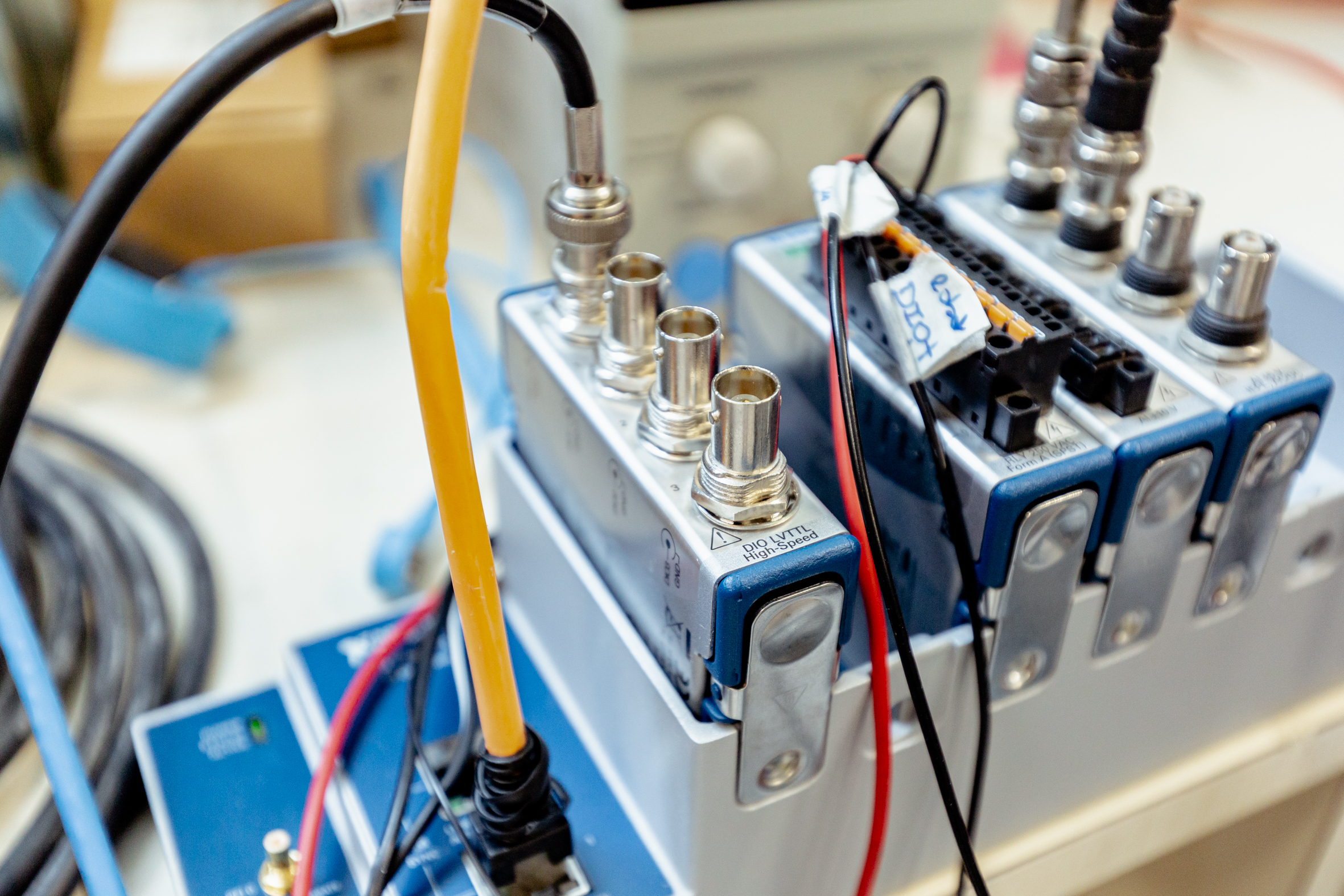

Our team includes certified LabVIEW developers and qualified Python developers, ensuring that the solutions we develop are not only robust but also state-of-the-art. We are equipped to handle the intricacies of both software and hardware aspects of quality inspection systems.

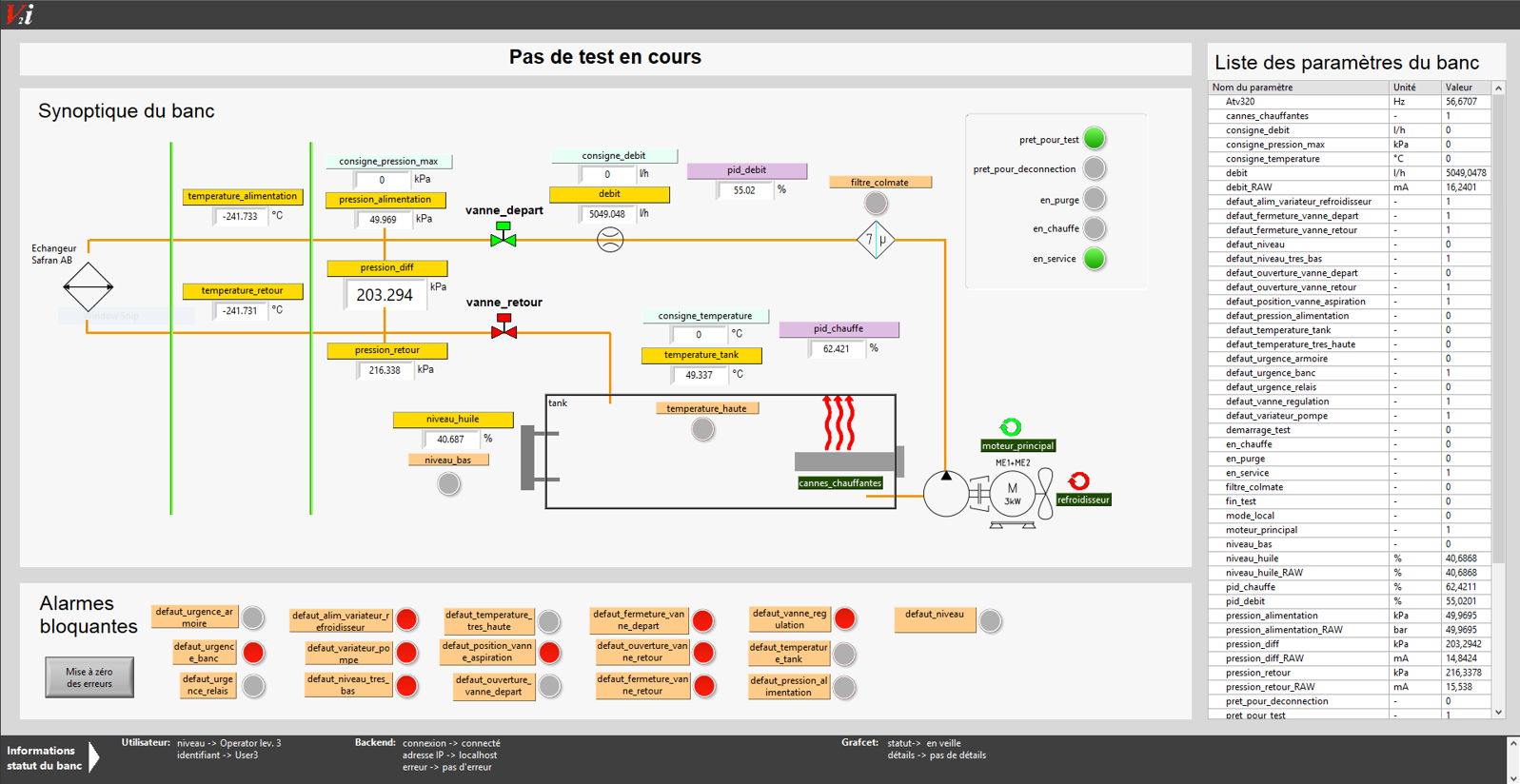

Customizable Human-Machine Interfaces (HMI):

We understand that each manufacturing setup has unique needs. That’s why we offer tailor-made HMI solutions that are intuitive and user-friendly, enabling easy monitoring and control of the quality inspection process.

Flexible Communication with PLCs:

Our systems are designed to communicate with programmable logic controllers (PLCs) using multiple methods, ensuring consistent integration and real-time data exchange across various components of the production line.

Multi-Device Acquisition Capability:

We have the expertise to combine multiple acquisition devices within a single inspection system, providing a comprehensive solution that covers all angles and aspects of the manufacturing process.

Extensive Portfolio of Successful Use Cases:

With a vast array of successful implementations across different industries, our solutions are proven to enhance productivity and reliability. Our portfolio demonstrates our ability to tailor solutions to meet specific industry needs and challenges.

- Precision: Reduces human error with automated accuracy.

- Speed: Increases inspection throughput.

- Cost Efficiency: Cuts labor costs and waste.

- Adaptable: Customizable and scalable to needs.

- Cutting-Edge Tech: Uses advanced 3D and AI tools.

- Proven Results: Backed by successful industry implementations.

Control Systems for Civil Engineering

Most European civil engineering structures were built between a few decades ago, with a planned lifetime of 40 or 50 years. Throughout their service, these structures are exposed to environmental conditions and infrequent solicitations, despite minimal maintenance for financial reasons. Today, this means many of them are in a condition of serious deterioration and require a monitoring of their structural integrity.

For years, public authorities operating civil engineering structures performed regular visual inspections on the most critical facilities, at a minimum. With the development of increasingly high-performing hardware and digitalisation, remote and continuous monitoring of these structures has become another viable option.

Thanks to a long-term partnership with Professor Vincent Denoël from the University of Liege, and several projects carried out for the Wallonia Region, V2i has developed specific and autonomous solutions for real-time remote monitoring of civil engineering structures. This ensures our solution to integrate the most advanced data-analysis techniques, while perfectly satisfying the requests of administrators and inspectors.

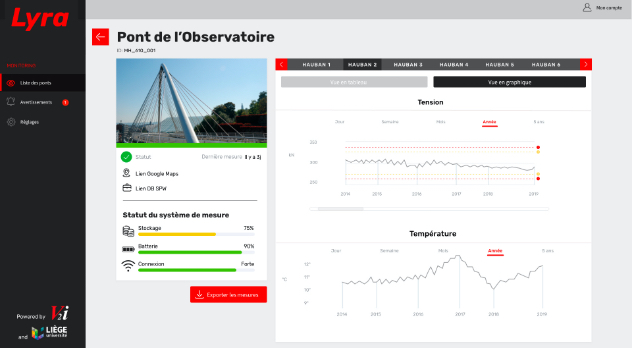

LYRA solution

Discover some of our references here!

Pont de Lanaye

Pont de la Gare des Guillemins

Pont de Wandre

Belle Liégeoise

Pont d'Harchies

Enjambée

Pont de Chaudfontaine

Arc Majeur

Monitoring Devices for the Steel Industry

Today, many operating production lines face big challenges: despite getting older, as they were built a few decades ago, their capacity has to be increased to enable the operator to process a wider range of steel grades. This is especially true for plants processing products with a high added value, like those dedicated to the automotive industry. These lines often require modernisation or revamping to meet new market requirements.

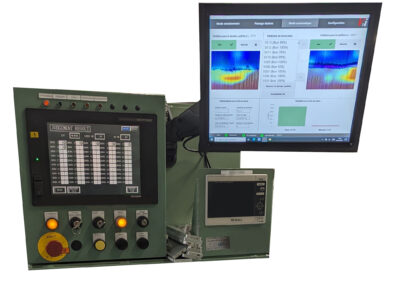

Thanks to partnerships with several steel producers, V2i developed specific data-acquisition solutions enabling the monitoring of machinery and equipment in the steel industry, for real-time quality-control purposes and long-term maintenance. These tailor-made solutions include specific instrumentation, acquisition hardware, data-analysis software tools and a user-friendly interface.

These systems are based on long-standing expertise in working with experimented field engineers and technicians from leaders in the steel industry. This is why V2i’s solutions respond so well to operator demands and contribute so efficiently to decreasing down time and increasing productivity.

Thanks to its expertise in data acquisition and data analysis, and with the help of long-term partners in this sector, V2i developed several specific solutions dedicated to the steel industry.

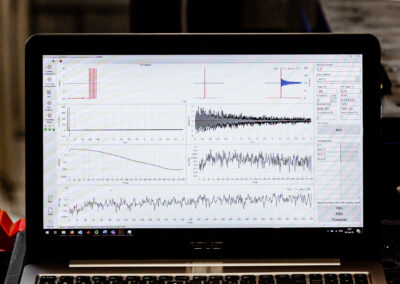

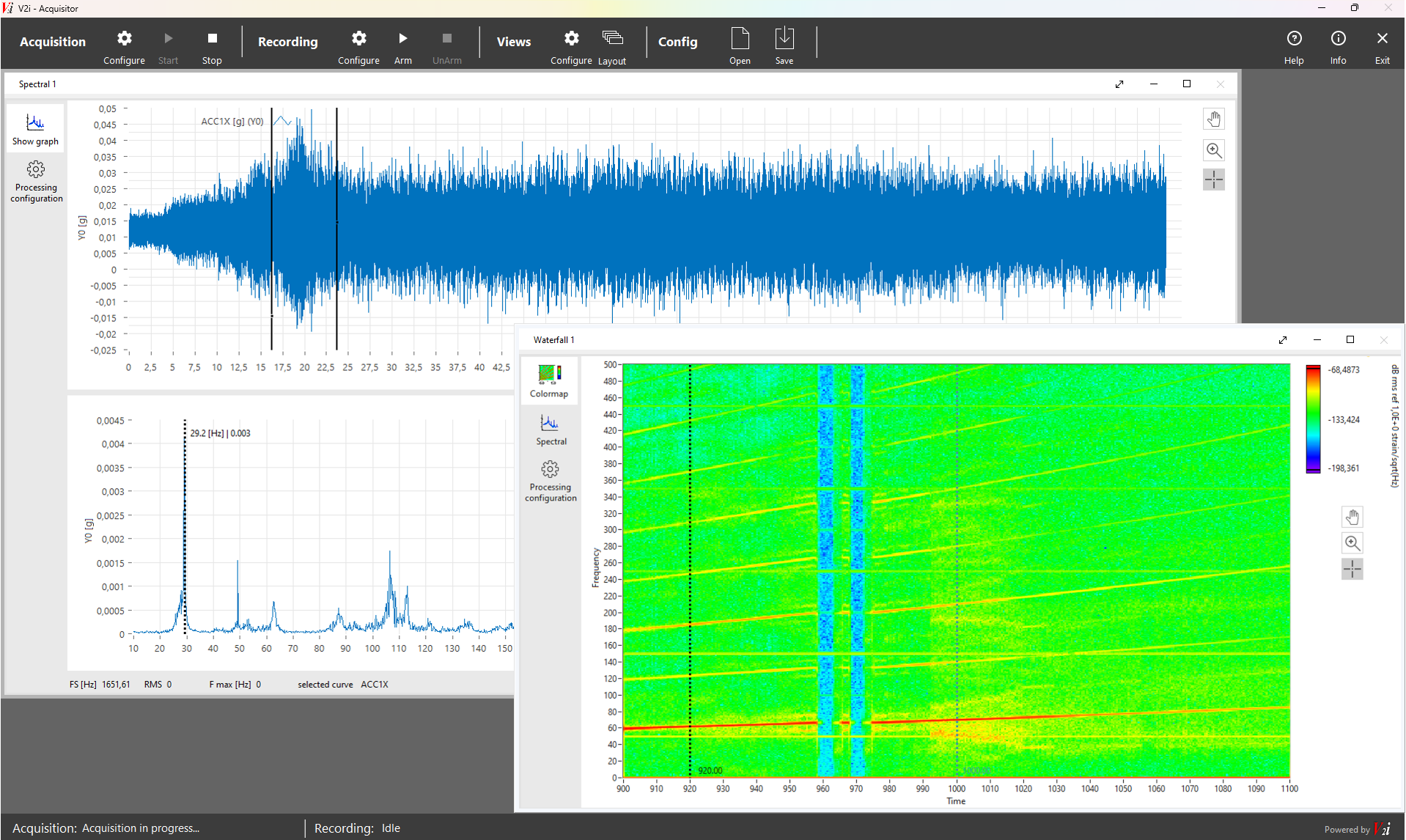

Acquisitor – Data Acquisition with Advanced Processing Capabilities

Acquisitor is a powerful data logging and monitoring software developed by V2i. It’s designed to simplify the process of acquiring, visualizing, and analyzing data from a variety of sensors and measurement instruments.

Ease of Use: Intuitive user interface for quick setup.

Versatility: Compatible with various data acquisition hardware.

Customization: Allows for tailored configurations and calculations.

Scalability: Adaptable to different measurement needs and system sizes.

Real-time Visualization: Provides live data monitoring during tests.

Advanced Signal Processing: Perform real-time analysis, including filtering and FFT.

Data Logging and Export: Supports logging in multiple formats for analysis

Acquisitor Data Display

Structural Integrity: Evaluate how structures respond to sudden loads and analyze dynamic behavior.

Performance Optimization: Determine natural frequencies and mode shapes to avoid resonance and enhance efficiency.

Noise and Vibration Control: Identify and mitigate noise and vibration issues.

Failure Prediction: Identify potential failure modes and locations, enabling preventive maintenance strategies.

Quality Assurance: Ensure products meet standards through experimental testing.

Model Calibration: Validate and improve accuracy of simulation models with experimental data.

Comprehensive Data Analysis: Acquisitor offers robust tools for efficient data analysis, visualization, and reporting of modal test results.

Test Benches for Aeronautics and Industrial Applications

Since industrial equipment is made of a collection of mechanical and electronic parts, its manufacturer or integrator needs to verify that its actual performances meet specifications. This is why test benches are so important for industry: they make it possible to validate a design or model for engineering or quality-control purposes.

As they combine expertise in instrumentation, acquisition and analysis of experimental data, tailor-made development of software tools and structural dynamics, V2i experts offer their partner tailor-made solutions to monitor their specific test bench.